About Us

We are a startup dedicated to developing specialized software for the techno-economic evaluation of green hydrogen projects. Our commitment is to integrate technological innovation and an environmental vision to drive the energy transition.

Mision

We provide optimization tools and professional services to support the global adoption of green hydrogen.

Science & Industry

We connect science and industry to transform knowledge into scalable green hydrogen solutions.

AI-Powered Solutions

Our AI-driven platform assists decision-makers by configuring critical parameters and delivering precise insights across the green hydrogen value chain.

Vision

We aim to shape a clean and sustainable energy future by positioning green hydrogen as a key driver of the global energy transition.

Why Green Hydrogen?

The hydrogen economy is crucial for achieving net-zero emissions by 2050. While energy efficiency and renewables can cover 70% of the required reductions, sectors like heavy industry and long-distance transport need alternatives like hydrogen. Hydrogen is expected to contribute 10% to emission reductions and meet 12% of energy demand by 2050. Currently, hydrogen production relies mainly on fossil fuels, but green hydrogen, produced through renewable electrolysis, has great potential. Investments in green hydrogen production facilities are increasing, highlighting its importance in the transition to a cleaner, more sustainable energy future.

Our Services

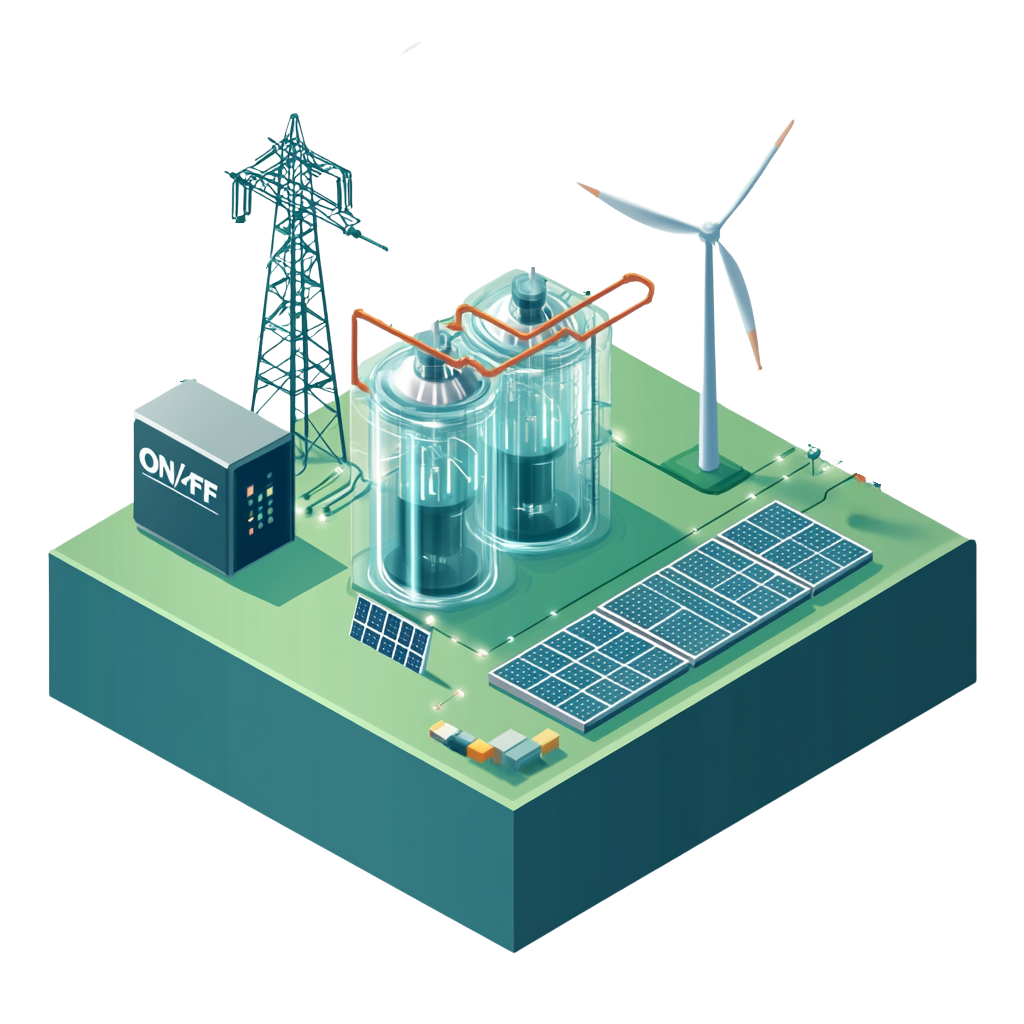

Advanced modeling tools for Power-to-X systems

H2 Smart Engine

Smart software to identify optimal Power-to-X sites, size capacities from renewables, analyze value chain costs, and unlock project potential.

AI Powered Production Dashboard

Dashboard for managing workflows and visualizing results like LCOH maps, hydrogen price breakdowns, energy balances, demand fulfillment, and more; all in one place.

Professional Power-to-X Services

Accelerate your Power-to-X transition with our experts: tailored simulations, techno-economic analysis, and optimized plants—ideal for companies without an in-house technical team.

H2 Smart Engine

Model Inputs

Model inputs include location, demand, COD, grid, technology specs, operational limits, and economic factors like debt, rates, and tariffs.

Processing & Optimization

We optimize plant sizing to minimize LCOH and use AI to assist with input selection and output interpretation.

Results Visualization

We offer detailed LCOH reports, financial analyses, avoided emissions assessments, scalability projections, and interactive maps to support better decision-making.

Model Inputs

Plant Design

- Project specifics, including location, hydrogen demand, grid connection, and commercial operation date (COD).

- Technical parameters such as technology selection, operational ranges, and system efficiencies.

- Economic factors like debt structure, interest rates, taxes, and import duties to ensure realistic project modeling.

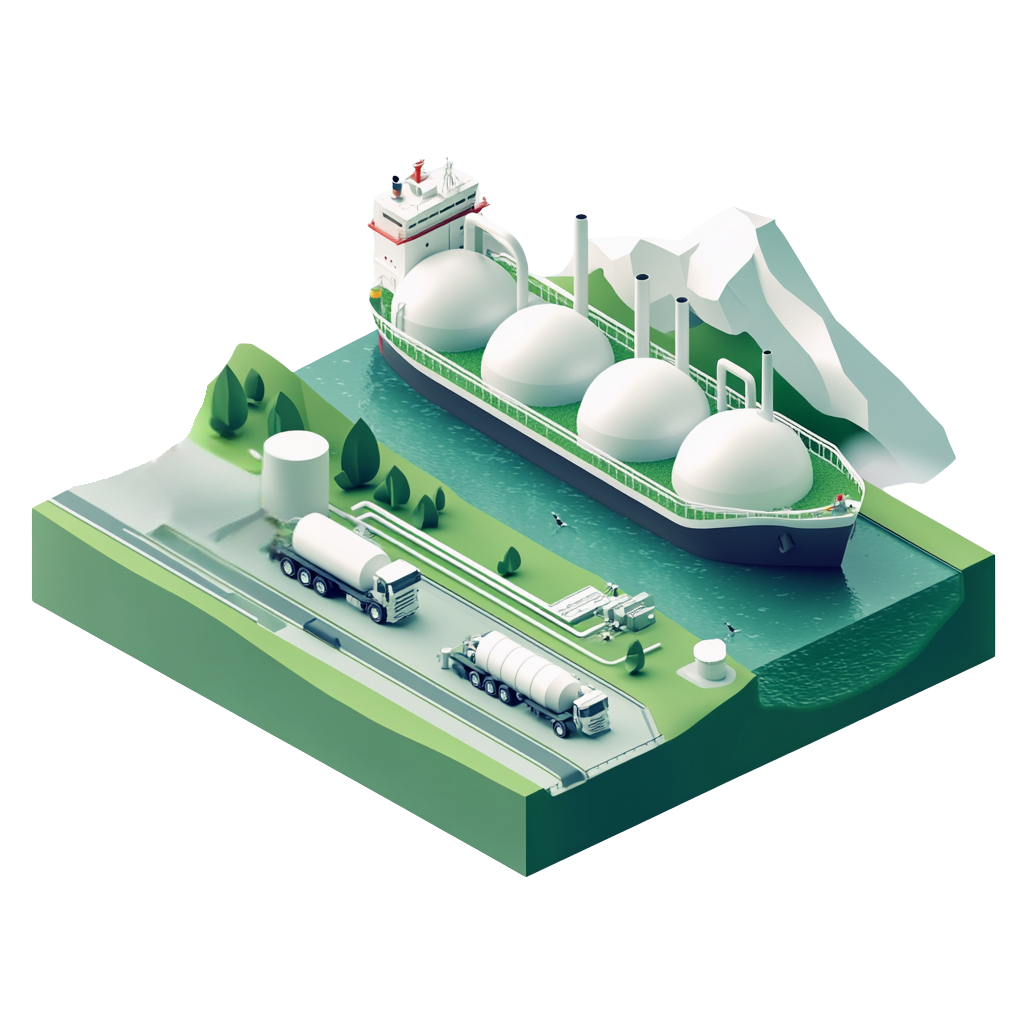

Storage & Transport

- The model incorporates costs for converting hydrogen into gaseous, liquid, LOHC, ammonia, and methanol forms, including energy and operational costs.

- Hydrogen transport costs, including land (truck, pipeline) and maritime, are considered, with an analysis of the respective infrastructure and operational expenses.

- Storage costs for hydrogen, including surface containers and salt caverns, are factored in based on the selected hydrogen vector.

Highly Customizable

- Default input parameters can be adjusted by the user to customize the model for specific project needs.

- Grid connection, interactions, and constraints are fully integrated into the optimization model.

- Demand transport distance, constraints, and green hydrogen certification schemes can be incorporated into the optimization process.

Economic Parameters

- Country-specific parameters like customs duties and incentives are included in LCOE and LCOH estimations.

- Financial structuring, including debt-equity ratios and interest rates, can be integrated into the analysis.

- Contractual terms such as delivery windows, hydrogen vector, and penalties are considered in the modeling.

Hydrogen Vectors

- The model includes conversion costs (CAPEX, and OPEX) for gaseous, liquid, LOHC, ammonia, and methanol, covering energy use.

- Conversion, transport, and storage processes are interconnected and modeled as an integrated value chain.

- Users can select hydrogen vectors to analyze based on project-specific needs and constraints.

Model Outputs

Macro Area Analysis

Generation of heatmaps to identify optimal PtX project sites, integrating renewable resource availability, distances to power grids and demand points, environmental constraints, and spatial suitability for informed decision-making.

Energy and Mass Balance

Hourly-step analysis to produce energy flows, hydrogen production, and mass balances across all system stages. Includes consumption, efficiency metrics, and process losses for precise performance analysis and optimization.

Interactive Dashboards and Intelligent Reports

Customizable dashboards with drag-and-drop tools to visualize LCOH, energy flows, emissions, and financial metrics. Export interactive charts, PDF reports, or raw data. Tailor views by timeframe, technology, or location for stakeholder-specific insights.

LCOE Assessment

Calculates the Levelized Cost of Energy (LCOE) incorporating regional taxes, subsidies, and current promotion schemes. Provides comparative scenarios with/without incentives, sensitivity analysis, and break-even points for informed decision-making in renewable energy projects.

LCOH Calculation

Detailed Levelized Cost of Hydrogen breakdown covering production, purification, compression, transport (pipeline/truck/ship), and storage. Includes CAPEX, OPEX, energy inputs, and lifetime degradation for accurate project benchmarking.

Chain-wide Emissions Estimation & Certification Protocols

Quantifies CO2eq emissions across the full value chain (well-to-gate), including production, compression, and distribution. Integrates international protocols to generate auditable reports and certification-ready documentation.

Out Team

We are four co-founders with extensive experience in Engineering, Renewable Energy, and Technology Development. Our expertise spans hydrogen technologies, energy transition, and advanced modeling and optimization.

PhD. Eng. Gabriel Correa Perelmuter

Chief Executive Officer (CEO)PhD in Energy and Electromechanical Engineering, Scientific Researcher and University Professor, with extensive experience in hydrogen projects and industrial development.

PhD M.Sc. Eng. Nicolás Ibagon

Chief Product Officer (CPO)PhD in Energy, Master of Science in Energy and Mechanical Engineering with extensive experience in hydrogen projects and energy transition initiatives across Latin America, Europe, and Africa.

PhD. Eng. Pedro Muñoz

Chief Scientific Officer (CSO)PhD in Engineering Sciences and Electromechanical Engineering, expert in multiphysics modeling and techno-economic analysis of batteries, fuel cells, and electrolyzers.

M.Sc. Eng. Jorge Saffe

Chief Technology Officer (CTO)Master of Science in Remote Sensors and Computer Engineering, specialist in software development and cloud systems, with over 15 scientific and technological projects implemented.

Our Partners

Trust in Us

News

⚡ Spain’s Recent Electricity Shutdown: A Wake-Up Call — and an Opportunity — for Green Hydrogen ⚡

Spain’s Recent Electricity Shutdown

Contact Us

Ready to boost your green hydrogen projects? Send us your questions or comments.

Location

Córdoba, Argentina

Call Us

+54 351 3337718

Write to Us

info@h2hydra.com